Application of CoolDrive A8 in six joint industrial robot

Abstract: The purpose of this paper is to introduce the application of Cooldrive A8 servo driver in 6-axis articulated industrial robot, and to provide a complete solution of robot electronic control system for customers.

Key words: Tsino Dynatron CoolDrive A8 industrial robot high end servo

1、overview

In recent years, China's industrial robots have seen rapid growth in both new installation and ownership. At present, the total number of industrial robots is close to 100000. According to research institutions, China's industrial robots market will grow at an annual rate of 20% in the future. Although the robot application has been developed rapidly in China, the robot market in China is still dominated by foreign enterprises, and the market share of local enterprises is only 4%. One of the main reasons is that the localization process of the core parts of the robot is slow. Domestic robot manufacturers can only import foreign products, resulting in high cost of the whole machine, which is at a disadvantage in the competition with foreign manufacturers.

CoolDrive A8 servo drive is the first networked modular servo drive product newly launched by Tsino Dynatron Electric Technology (Beijing) Co., Ltd. in China. It integrates a number of innovative technologies such as common DC bus, energy efficiency management, functional safety, multi axis synchronization, etc. to provide customers with a more energy-saving, flexible and safe servo system. Cooldrive A8 is very suitable for the industrial robot industry in terms of product form and function. It can completely replace similar foreign products and provide customers with more cost-effective solutions.

2. Domestic 50kg six joint industrial robot

The 50kg six joint industrial robot used in this project is the latest model made in China, which has the characteristics of compact structure, high joint speed, fast dynamic response, high precision and strong overload capacity. The electric control system adopts the bus structure, which is easy to expand and apply. Suitable for handling, laser cutting, polishing and other occasions. The product performance is as follows:

3. System design

3.1 customer requirements

The customer's 6-joint industrial robot is required to achieve high joint speed and repetitive positioning accuracy, while maintaining the stability of the robot when running on load. In addition, the customer requires that the internal functional parameters of the servo driver can be manually set online through the controller, so as to achieve accurate control.

3.2 design difficulties

Industrial robot is a very typical multi axis control system. In order to make the robot achieve high precision of repeated positioning, in addition to the strong path planning algorithm and interpolation function of the controller, the servo driver must also ensure that all joints are strictly synchronized when executing the controller position command. In order to improve the speed of the robot, it is necessary for the servo system to have strong instantaneous overload ability and high dynamic response characteristics.

How to reduce the vibration of robot in the process of operation is always a problem of robot servo system, which is also a reason that many domestic servo products can not be applied to industrial robots.

Vibration mainly occurs in two working conditions, one is when the robot starts and stops, the robot body and front edge ill vibrate; the other is when the robot runs at high speed and moves in a large range, the body will vibrate and the running track will deviate greatly. The main reason for the vibration is that the inertia of each joint of the robot has changed greatly. In order to eliminate the vibration, various feed forward compensation control functions must be added to the servo drive.

3.2 system scheme design

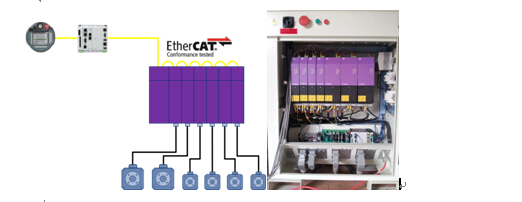

Through the in-depth analysis of customers' needs, we designed the electronic control system solution of "Keba controller + cooldrive A8" servo driver for customers.

The advantages of this system are:

1) Robot specific control system

This project selects kemotion control system developed by Keba for robot industry, including controller, video teaching box and control software. Its controller and video teaching box support the high-speed industrial Ethernet communication of EtherCAT, which has high computing performance and communication speed.

Kemotion also provides a powerful robot control software, in which a variety of types of robot path planning models are built in, which can quickly complete the development of the robot; at the same time, the software also provides a wealth of compensation algorithms and interpolation functions to ensure the control accuracy of the robot.

2) CoolDrive A8 High performance servo driver

CoolDrive A8 is the first product that has passed the ETG consistency test in China, so it can well cooperate with Keba controller; meanwhile, the cycle time of current ring, speed ring and position ring built in CoolDrive A8 has reached 62.5us, 125us and 250us respectively, and the frequency response has reached 3kHz, which fully meets the requirements of industrial robots for dynamic response and synchronization.

To solve the problem of robot vibration, CoolDrive A8 adds forward compensation algorithm of speed and acceleration, torque compensation and other compensation algorithms, and develops the functions of Positioning vibration suppression inertia forward, etc., which better solves the vibration generated by the robot body in high-speed operation and rapid positioning. In addition, CoolDrive A8 also adds motor flux weakening control technology to realize the light load and high-speed operation of the robot, and adds encoder signal correction technology to improve the stability of the robot and reduce the noise during operation.

CoolDrive A8 also adopts modular design innovatively among domestic servo manufacturers. The whole system is composed of rectifier module and motor drive module, which are connected by DC bus. This structure is convenient for users to expand the system, and the connection is very simple. The DC bus can also improve the energy efficiency of the system, making the equipment more energy-saving. CoolDrive A8 also has built-in STO, SS1, SS2 and other safety functions. In case of emergency, it can park safely according to the predetermined rules to protect the safety of equipment and personnel.

3). Actual performance test of robot

In the actual test process, the robot will vibrate obviously when it is running under full load without adding the compensation algorithms such as velocity, acceleration feed forward compensation and torque compensation. At the moment when the robot starts, if the moment compensation is not given in advance, Front edge of the robot body

will sink due to the action of gravity, which is commonly known as "nodding". When the robot stops quickly from high-speed running, if there is no " Positioning vibration suppression " function, the robot will experience jitter due to the sudden change of inertia.

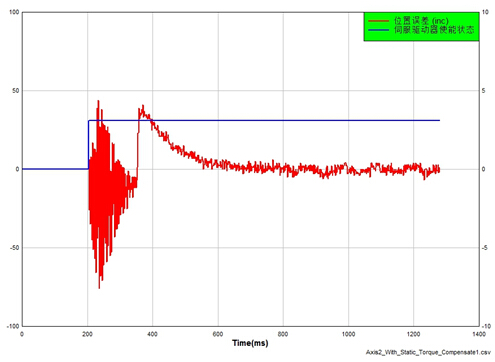

The figure below shows the position error of the robot when the compensation and vibration suppression functions are not turned on, and the obvious vibration phenomenon can be seen.

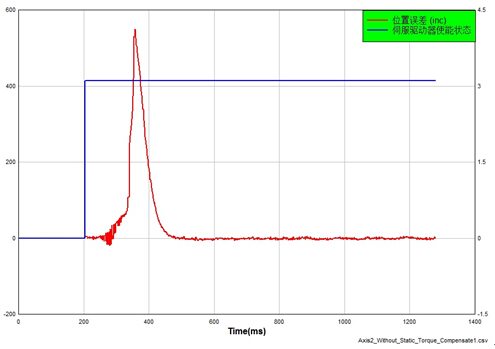

The figure below shows the position error of the robot body after the compensation and vibration suppression functions are turned on. It can be seen that the vibration of the robot body has been effectively suppressed.

5. Conclusion

Tsino Dynatron is committed to providing domestic high-end servo system for domestic robot manufacturers, which can meet the requirements of robot on servo system in performance and function, and has no high price of foreign products, so as to realize localization of key parts of robot, reduce the overall cost of domestic robot manufacturers, and improve the competitiveness of domestic robots.